Home › Design information › Quotation language › Plate finish › Stainless steel finish

Stainless steel finish

2b/finish 2b

If, in the case of stainless steel, a thinner sheet is the most standard sheet (at Alinco up to and incl. 6 mm). If a plate with a low roughness value and very good quality, is not suitable for aesthetic purposes, because it may still bear stamps from the factory, among other blemishes. This plate cannot be kept scratch-free due to handling and production.

When scratch protection is important, however, you need to order sheets with 2b finish and protective film! This only costs a few cents per kilo more. The disadvantage is that the film must be peeled off afterwards.

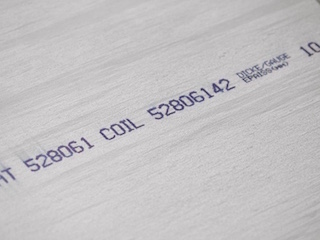

Stainless steel with protective film

2b finish with a PVC protective film against scratches. Note: the film does not prevent material grade, melting number, etc. stamps from being applied under the film.

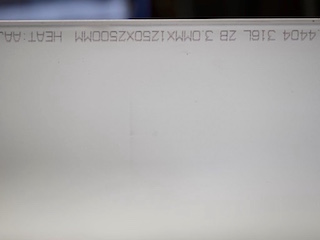

Hot rolled

Is harsher than 2b finish. Even though the plate shown on the photo may look fine, it cannot be used for aesthetic applications. It is a rather raw and rough plate finish with visible stamps from the factory. Slight damage due to handling and production cannot be excluded because the plate is not available with protective film.

Alinco uses 2b finish as standard up to and incl. a sheet thickness of 6 mm for stainless steel; from 8 mm thickness onwards, these sheets are only available in hot-rolled and polished sheet finishes. In addition, Alinco always has hot-rolled sheets in stock in 3, 4 and 5 mm thicknesses for customers who prefer this for an aesthetic application.

Sanding/grinding/brushing/unidirectional brushing/K320

Always according to our standard K320 satin polishing (which is also the market standard; as a rule, we don’t suggest different finishes from this standard grain because they can prove expensive since we don’t usually have them in stock). Unless specified otherwise, plates are always polished on one side. Sanding, grinding and brushing are used interchangeably on the market; sometimes ‘polishing’ is also used, which is a confusing term. These terms all describe the same finishing process.

To differentiate it from directionless brushing, this finish is sometimes called "unidirectional brushed stainless steel". Obviously, unidirectional brushing refers to the direction of the plate sanding or grinding process, which is visible to the naked eye in the form of tiny lines.

Customers may ask for a sample in the request for a quotation.

Double-sided grinding/sanding/brushing

Same appearance as with brushed K320 satin finish but on both sides.

Directionless brushing/sanding/grinding

Brush strokes in all kinds of directions is a popular finish for kitchen countertops. In addition to its aesthetic aspect, this finish makes sure new scratches stand out less. This is also used in industrial applications. Customers may ask for a sample in the request for a quotation. As a rule, we use fairly fine sanding belts, but a rough execution is also possible.