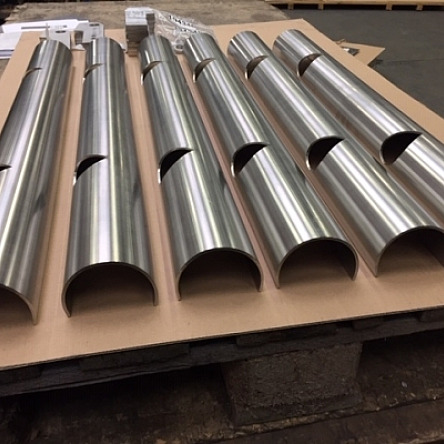

Plate rolling or perhaps bending work?

What do you think? The sheets in the attached photo are 8 mm thick. Are they rolled or folded?

If I tell you that a sheet is 8 mm thick…

Think about it from a technical viewpoint: thick sheets should always be rolled on a sturdy plate bending roll - i.e. larger rolls. There is no standard length plate rolling machine with rolls of e.g. 150 mm that can roll an 8 mm sheet... So yes, we folded these sheets using our special bending technique and did not roll them.

Time and again we need to convince prospects that bending segments into shape may not necessarily produce visible and folds... Obviously, if the segment does not go sufficiently through the folding process, it will be angular. Consequently, when preparing a quotation, it is important to check how many folds are required over the entire circumference. Creating a perfectly round shape is however possible.

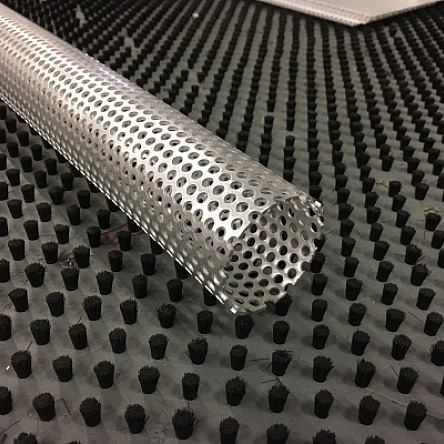

Given the choice, of course, rollers / plate rolling mills are preferred for economic reasons: it remains a faster and therefore cheaper process.

Except when tolerances and dimensional stability are very important: parts produced through the bending segment process are dimensionally more stable.

Karine De Bie