Alinco in de pers (US en Canada)

Alinco verscheen de laatste jaren een aantal keer in de Nederlandse en Vlaamse pers nav diverse onderwerpen. Recentelijk kwam er een delegatie uit de US en Canada langs voor enkele publicaties in tijdschriften en op websites ginder.

De artikels wilden de kennis en know-how van LVD in de kijker zetten. Alinco heeft 2 lasersnijmachines, 1 knipschaar en 6 plooibanken staan van LVD.

Hieronder het ganse artikel.

Alinco

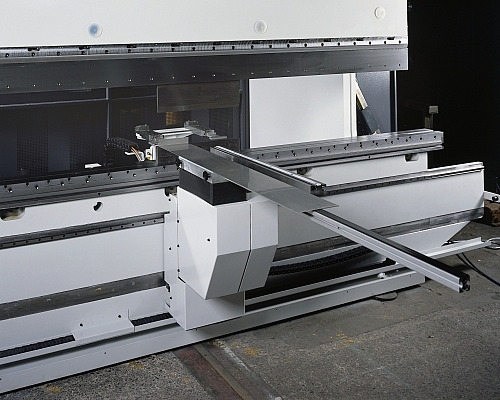

Alinco is specialized in sheeting and metal constructions, both for subcontracting and projects. Because of the company’s size, machinery and technical expertise, they are a market leader in their sector. The company has had an excellent, long-term relationship with LVD and has seven of the company’s press brakes on their shop floor, along with two lasers. Around 50 people work at the company.

Alinco considers their flexibility and turnaround time a big advantage they hold over their competition. In an era of just-in-time delivery, the company is a bit of an anomaly – they actually carry a vast amount of sheet metal stock, including B265 titanium, various grades of steel, and various grades of stainless steel. This stock allows them to turn around product faster, and at a more reasonable price for their clients.

“We order about 20-30 tonnes of a raw stock at one time,” says Karine De Bie, manager of Alinco. “Not only does this mean we can offer short delivery times, but we can also trace the origins of the stock we are using for clients, if necessary.

Of the seven press brakes the company maintains, four run at least eight hours a day. With two lasers on the shop floor, the company has arranged for one – the Impuls 4020-R – to do short-run, quick turnaround jobs, and the other – the Axel 3015S – to take on long runs.

The Impuls 4020R laser system combines the flexibility of rotary and flat plate cutting. A compact flying optics laser cutting machine, it features two shuttle tables and a 280 mm fully programmable Z-axis for use with an optional rotary axis or for processing pre-formed parts.

Users can load the optional rotary while the machine processes flat plate or load the table while processing pre-formed parts or tubes on the rotary axis. Changeover can be accomplished with minimal intervention.

Impuls 4020R processes tubes up to 500 mm diameter with a weight of 950 kg. Flat sheet cutting can continue during rotary set-up or loading/unloading of the tubes.

“About one third of what is cut on this machine is tube work,” says De Bie.

The Axel 3015S has a high performance linear motor that delivers high-speed cutting for fast, continuous processing of parts. It achieves cutting speeds up to 40 m/min (1575 IPM) and has a 5 x 10 m work table area.

Alinco has the laser fully integrated with a programmable load/unload system, and maintains three loading stations in front of the machine. The laser is equipped with a quick change lens (5", 7.5" and 10") as standard.

These are just three examples of how companies can right-size their equipment and automation investments to ensure that throughput remains steady and clients receive what they want.

It's worth considering what the bottlenecks are in your processes. Is there a way to remove that bottleneck with a relatively simple upgrade? How much can one or two investments improve your quality, efficiency and bottom line?

For more information on all of the machines discussed here, visit www.lvdgroup.com.